PRODUCT

CERTIFICATION

EXHIBITIONS INFO

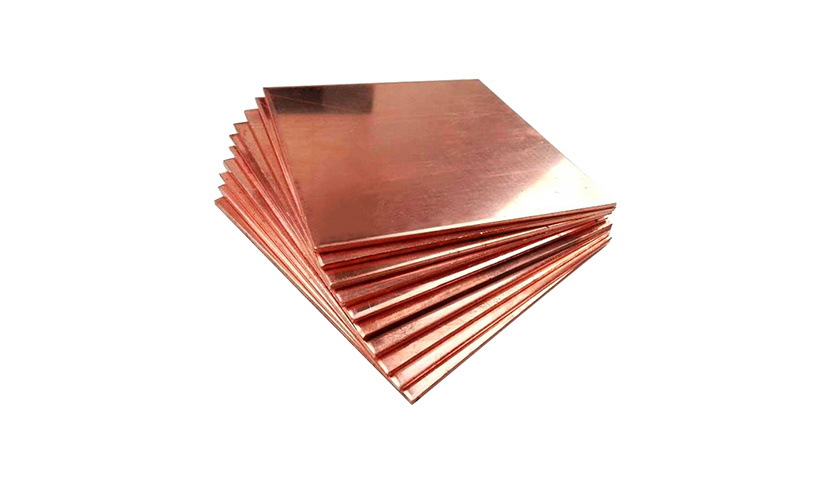

Copper Plate

UNS C12000 copper has 95% IACS conductivity, low residual phosphorus, and high embrittlement resistance. It has a good electrical conductivity and excellent welding and soldering properties. It can be formed excellent, either hot or cold.

General Description C12200, Phosphorus deoxidised copper, has been made weldable and brazeable by deoxidising with phosphorus. It is widely used as flat products and tubing, especially where it is to be welded or brazed.

C11000 Electrolytic Tough Pitch (ETP) Copper is known for its high electrical and thermal conductivity, good corrosion resistance and solderability. C11000 copper is used for welding fixtures, anodes, bus bar in electrical power installations, ground straps, commutators and current-carrying hardware.

The purity of TU2 / C10200 oxygen free reaches 99.95%, the oxygen content is not more than 0.005%, and the total impurity content is not more than 0.05%. TU2/ C10200 oxygen-free copper has excellent cold and hot processing performance.

C10100 Oxygen-Free Electronic Copper, also known as OFE, is a 99.99% pure copper with 0.0005% oxygen content. C101 achieves a minimum 101% IACS conductivity rating. This copper is finished to a final form in a carefully regulated, oxygen-free environment.

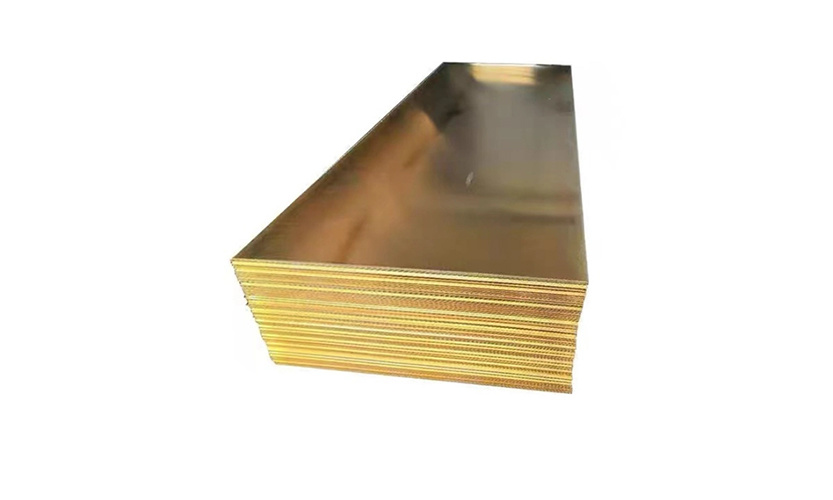

Alloy C21000 is a yellow brass. With a small zinc addition, the alloy is stronger and more durable than pure copper, while exhibiting excellent formability, corrosion resistance, and solderability amongst the brasses. C21000 finds use in applications from connector components to fasteners.

C22000 Commercial Bronze is a copper alloy that is nominally composed of 90% copper and 10% zinc. Though, due to the fact that it has more zinc than tin, this alloy can actually be categorized as brass. It gets its reddish color from the high amount of copper.

C23000 brass is the most durable of all metals for commercial water pipe in the practical price range. Excellent for its resistance to dezincification and season cracking for which the high copper brasses are known. Moderate strength and good retention of spring properties.

C24000 brass with a nominal composition of 80 % copper and 20 % zinc approaches the mechanical properties of CuZn30 but with corrosion properties only slightly inferior to CuZn15. This alloy has a color between yellow and golden red and finds distinctive uses in decorative trim applications.

The alloy is the most common brass in sheet form. The alloy consists of the face centred cubic alpha phase, and has the optimum combination of strength and ductility in the copper-zinc series. C26000 has the distinctive clear bright yellow colour normally associated with 'brass'.

Yellow brass UNS C27000 is commonly referred to as copper-zinc brass. UNS C27000 shows excellent cold working properties which make it ideal for machining. Architects prefer brass for their shaping ability and colour. Brass is recycled efficiently and proves economical.

Lead increases the machinability of brass as well as increasing its strength and resistance to corrosion. The addition of lead also seals shrinkage pores to provide pressure tightness. Brasses can contain up to 3.5 percent in lead contents, and are classified as low, medium, or high-leaded.