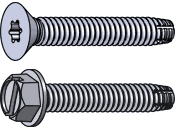

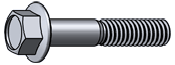

Carriage/Hex Bolt

- Product Description

-

Fastener Categories

Wood Screws

Screws with a smooth shank and tapered point for use in wood.

Abbreviated WSMachine Screws

Screws with threads for use with a nut or tapped hole.

Abbreviated MSThread Cutting Machine Screws

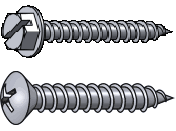

Machine screws with a thread cutting (self tapping) point.Sheet Metal Screws

Fully threaded screws with a point for use in sheet metal.

Abbreviated SMS

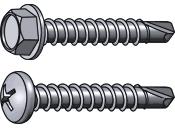

Self Drilling SMS

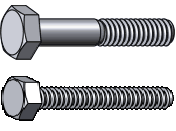

A Sheet metal screw with a self drilling point.Hex Bolts

Bolts with a hexagonal head with threads for use with a nut or tapped hole.

Abbreviated HHMB or HXBTCarriage Bolts

Bolts with a smooth rounded head that has a small square section underneath.Lag Bolts

Bolts with a wood thread

and pointed tip.

Abbreviated Lag

Flange Bolts

Flange bolts have a flange on the bottom of the head that distributes the load like a washer.Socket Screws

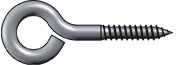

Socket screws, also known as Allen head, are fastened with a hex Allen wrench.Eye Bolts

A bolt with a circular ring on the head end. Used for attaching rope or chain.Eye Lags

Similar to an eye bolt but with wood threads instead of machine thread.

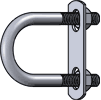

U-Bolts

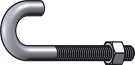

Bolts in U shape for attaching to pipe or other round surfaces. Also available with a square bend.J-Bolts

J shaped bolts are used for tie-downs or as an open eye bolt.Shoulder Bolts

Shoulder bolts (also known as stripper bolts) are used to create a pivot point.Elevator Bolts

Elevator bolts are often used in conveyor systems. They have a large, flat head.

Sex Bolts

Sex bolts (a.k.a. barrel nuts or Chicago bolts) have a female thread and are used for through bolting applications where a head is desired on both sides of the joint.Mating Screws

Mating screws have a shoulder that matches the diameter of the sex bolts they are used with.Hanger Bolts

Hanger bolts have wood thread on one end and machine thread on the other end.Set Screws

Machine screws with no head for screwing all the way into threaded holes.Head Styles

Flat

A countersunk head with a flat top.Abbreviated FHOval

A countersunk head with a rounded top.Abbreviated OH or OVPan

A slightly rounded head with short vertical sides.Abbreviated PNTruss

An extra wide head with a rounded top.

Round

A domed head.

Abbreviated RHHex

A hexagonal Head.

Abbreviated HH or HXHex Washer

A hex head with built

in washer.Slotted Hex Washer

A hex head with built in washer and a slot.

Socket Cap

A small cylindrical head using a socket drive.Button

A low profile rounded head using a socket drive.Drive Types

Phillips

The standard drive type for most screws.

Abbreviated PHFrearson

Similar to Phillips. Requires a Frearson driver for installation.Slotted

A slot in the head.

Abbreviated SLCombination

A combination of slotted and Phillips drives.

Abbreviated Combo

Socket, Hex or Allen

A hexagonal hole for use with an Allen wrench.One Way

Installs with a normal slotted driver but can not be removed without special tools.Square

Also known as Robertson drive.

Abbreviated SQ or SD.Star

Also known as Torx. A six-pointed star pattern, specifically designed to prevent cam-out and stripped heads.Bolt Grade Markings and Strength Chart US Bolts Head Marking Grade and Material Nominal Size Range(inches) Mechanical Properties Proof Load(psi) Min. Yield Strength(psi) Min. Tensile Strength(psi)

307A

Low carbon steel1/4" thru 4" N/A N/A 60,000

No MarkingsGrade 2

Low or medium carbon steel1/4" thru 3/4" 55,000 57,000 74,000 Over 3/4" thru 1-1/2" 33,000 36,000 60,000

3 Radial LinesGrade 5

Medium carbon steel, quenched and tempered1/4" thru 1" 85,000 92,000 120,000 Over 1" thru 1-1/2" 74,000 81,000 105,000

6 Radial LinesGrade 8

Medium carbon alloy steel, quenched and tempered1/4" thru 1-1/2" 120,000 130,000 150,000

Stainless Markings VaryGrade A325

Carbon or alloy steel with or without boron1/2" thru 1-1/2" 85,000 92,000 120,000 Stainless Markings Vary 18-8 & 316 Stainless

Steel alloy with chromium and nickelAll sizes thru 1" N/A 20,000 Min. 65,000 Typical 65,000 Min. 100,000 – 150,000 Typical

651 Silicon bronze

An alloy of mostly copper and tin with a small amount of silicon1/4" thru 3/4" N/A 55,000 70,000 7/8" thru 1-1/2" N/A 40,000 55,000

Aluminum 2024

Aluminum alloy with copper, magnesium and manganese; solution heat treated and age hardenedAll sizes N/A 36,000 55,000 Metric Bolts Head Marking Class and Material Nominal Size Range(mm) Mechanical Properties Proof Load(MPa) Min. Yield Strength(MPa) Min. Tensile Strength(MPa)

Class 8.8

Medium carbon steel, quenched and temperedAll sizes below 16mm 580 640 800 16mm - 72mm 600 660 830

Class 10.9

Alloy steel, quenched and tempered5mm - 100mm 830 940 1040

Class 12.9

Alloy steel, quenched and tempered1.6mm - 100mm 970 1100 1220 Usually Stamped A-2 or A-4 A-2 & A-4 Stainless

Steel alloy with chromium and nickelAll sizes thru 20mm N/A 210 Min. 450

Typical500 Min.

700 TypicalTensile Strength:The maximum load in tension (pulling apart) which a material can withstand before breaking or fracturing. Yield Strength:The maximum load at which a material exhibits a specific permanent deformation. Proof Load:An axial tensile load which the product must withstand without evidence of any permanent set. 1MPa = 1N/mm2= 145 pounds/inch2 Fastener material and coating

Fasteners come in a variety of materials. Selecting a material should be based on such considerations as environment (corrosive or temperature extremes), weight, magnetic properties, stresses, reusability, and expected life.

Steel: Most fasteners are made from steel. Specifications cover a broad range of mechanical properties that are indicated by a bolt-head marking system that identifies the fastener by grade. For example, SAE grades 2, 5, and 8 are most often specified. Common steels are SAE 1010 (machine screws, carriage bolts, and other fasteners without critical strength requirements); SAE 1018, 1020, 1021 (bright cap screws, special items); SAE 1038 (high-strength bolts, studs, nuts, cap screws); SAE 1041, 1045, 1330, 1340 (special high-strength requirements), and SAE 1100 series (resulfurized -- usually for nuts).

Aluminum: Aluminum alloys are the least costly, by volume, of all fastener metals. Aluminum fasteners are classified as hardenable and nonhardenable and weigh about one-third as much as steel. Some grades equal or even exceed the tensile strength of mild steel. The metal polishes to a high luster, has high thermal and electrical conductivity, is nonmagnetic, can be hardened by alloying, and has high corrosion resistance. Typical fastener alloys are 2024-T4 (cold-formed bolts, screws, rivets, machine-screw nuts), 2011-T3 (milled-from-bar nuts, screws, bolts), 1100 (cold-formed rivets), and 6061-T6 (nuts).

Brass: This metal is worked easily into shape and has adequate strength. Tensile strength or hardness is improved by cold working. Some brasses have a greater tensile strength than mild carbon steel, along with a higher resistance to corrosion. The metal is nonmagnetic and takes a high luster.

Copper: One of the most malleable of all metals, copper also has good corrosion resistance and the highest conductivity of all the nonprecious metals.

Copper:One of the most malleable of all metals, copper also has good corrosion resistance and the highest conductivity of all the nonprecious metals.

Copper is alloyed with silicon and manganese or aluminum for greater strength. Lead is added to give free-machining qualities. Typical alloys are high-silicon bronze, type A (hot-forged bolts, nuts; milled-from-bar bolts, nuts, setscrews); low-silicon bronze, type B (cold-formed bolts, nuts, rivets, screws); silicon-aluminum bronze (hot-forged products requiring special properties); and cupro-nickel, a copper-nickel alloy used for high strength and resistance to saltwater corrosion.

Nickel: Fasteners can be made from commercially pure (99.4%) metal, Monel, or Inconel. They are used where toughness, immunity to discoloration and corrosion, and strength at high temperatures are desired.

Pure nickel: Ideal for applications involving contamination, and strength retention at both high and subzero temperatures.

Monel: Combines relative economy with adaptability to cold heading and roll threading.

Inconel: Excellent for fasteners that must retain high strength and oxidation resistance at temperatures up to 1,600°F.

Stainless steels: Fasteners of this metal are used where corrosion, temperature, and strength are problems. They also produce a mirrorlike finish. There are three basic types:

Martensitic: Magnetic and hardenable. Common fastener alloys are Types 410, 416, and 431.

Ferritic: Magnetic and not hardenable by heat. Can be cold worked with reasonably good results. Used for economic reasons, and where corrosion-resistance requirements are not too severe. Best fastener alloy types are 430 and 430F.

Austenitic: Nonhardenable, nonmagnetic, and offers the greatest degree of corrosion resistance. Typical alloys are 18-8 and 300 series.

Titanium:Fasteners made from this material are used chiefly on aircraft. Titanium has excellent corrosion resistance and good high-temperature performance. These fasteners are most commonly used in joints loaded in shear but are also used in tension-loaded joints.

Beryllium:Exceptionally lightweight, beryllium fasteners are about 40% as heavy as titanium. Brittleness is a limitation to widespread use. Beryllium bolts are used primarily for applications where the shear requirement is at least 60 ksi.

Product Packaging

Waterproof paper, and steel strip packed. Standard Export Seaworthy Package.

Shipping Method

Shipping by containers / Shipping by bulk ship

Customized Services

Packaging and transportation methods can be customized according to customer requirements.

Tag list

TESTING EQUIPMENT

PMI Test

PMI Test 1

PMI Test 2

Component Analysis

Component Analysis 2

Size Inspection

RECOMMENDED

Thin/Dome Cap/Flange/Hex/Nyloc Nut

Nuts and bolts or screws screwed together to play a fastening role of the parts, all manufacturing machinery must use a component according to the different materials, divided into carbon steel, stainless steel, non-ferrous metals and other major types.

MOREExternal Tooth Lock/Flat/Inner Tooth Lock/Spring Washer

A washer is a loophole (usually in the middle) of a thin sheet (usually round) that is usually used to distribute the load to thread fasteners. Other uses are as spacers, springs (Belleville gaskets, wave gaskets), wear pads, pre-display devices, locking devices.

MORE