Stainless Steel/Carbon Steel/Alloy Flange

- Product Description

-

Flange Product Name Flange Grade Stainless Steel: ASTM A182 F304/F316/F321/F317/F309/F310/F347/F348

Carbon Steel:A105、A350、A694

Alloy steel:ASTM A182 F5、F9、F11、F22ASTM UNS 410,430,201,304,304L,321,316,316L,317L,347H,309S310S,904L,S32205,2507,254SMOS,32760,253MA,N08926,etc. EN 1.4301,1.4307,1.4541,1.4401,1.4404,1.4571,1.4438,1.4539,1.4547,14529,1.4562,1.4410,14878,1.4845,1.4828,1.4876

2.4858,2.4819,etc.Surface: Carbon steel:shot blasted,black painting,rust-proof oil,transparent oil,galvanizing,hot galvanizing

Alloy steel:Shot blasted,black painting,rust-proof oil,transparent oil,galvanizing,hot galvanizing

Stainless steel:pickled,PolishThickness: 0.3-150mm,(SCH10-XXS) Specifications: 10-1220mm,(3/8"-100") etc Pressure: PN0.5-PN500 Application: Chemical engineering, construction, drainage, petroleum, light and heavy industry,

plumbing, fire fighting, electric power, aerospace, shipbuilding and other basic projectsFlange sizes 1/2”-60” (DN15-DN3000) Thickness Schedule 10(S) to SCH 16 Flange facing

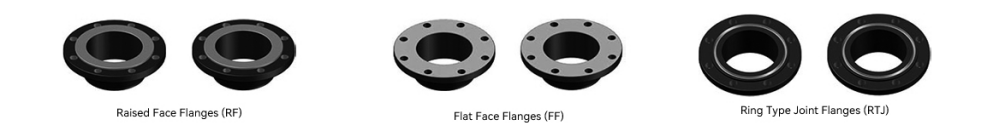

There are three primary types of flange facings. Not all facings are available with each end connection. This is based on the design of the flange and design of the piping system.

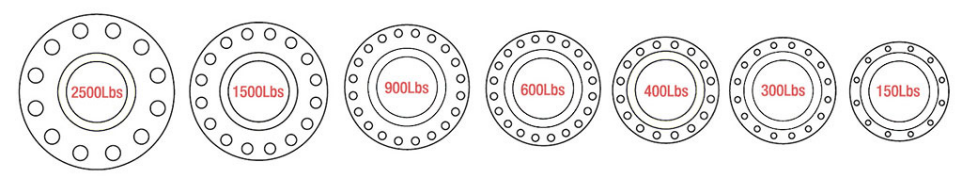

Flange pressure classes

Flange types

Blind flange

A blind flange, abbreviated as BF, is a piping component for covering or closing the end of a pipe, valve, vessel or tank.

Lap joint flange

A lap joint flange, abbreviated as LJF, is a flange that consists of two parts, a stub end and the backing flange.

In general, the thickness of the hub is between ¼” to 3/8”.

Raised face flange

the most common type of flange facing is the raised face flange, abbreviated as RF. It is used in almost all applications in high and low pressures and temperatures.

The face of the flange is either 1/16” or 1/4” depending on the pressure class. ANSI 300 and under have a 1/16” raised face and ANSI 400 and above have a 1/4” raised face.

Slip-on flange

Slip-on flanges, abbreviated as SOF, are designed to slip over the outside of pipe, long-tangent elbows, reducers, and swages.

Thread flange

The threaded flange, abbreviated as TRHF, is similar to a slip-on flange, but has internal threads. It is normally used for low pressure and not used where temperature or stress is very high. This flange has a raised face.

Socket weld flange

The socket weld flange, abbreviated as SWF, is similar to a slip-on flange, except only one fillet weld is made to the flange and pipe. Pipe is welded to socket weld flanges by inserting the pipe into the socket and backing the piping out between 1/16” and 1/8”.

Weld neck flange

the weld neck flange, abbreviated as WNF, is a flange type that is usually used with pipes, as opposed to pressure vessels.

Product Packaging

Waterproof paper, and steel strip packed. Standard Export Seaworthy Package.

Shipping Method

Shipping by containers / Shipping by bulk ship

Customized Services

Packaging and transportation methods can be customized according to customer requirements.

Tag list

TESTING EQUIPMENT

PMI Test

PMI Test 1

PMI Test 2

Component Analysis

Component Analysis 2

Size Inspection

RECOMMENDED

Stainless Steel/Carbon Steel/Alloy Reducer

Concentric reducer is a kind of fitting that be used for reducing piping size. Concentric reducer is most commonly used and often eccentric reducer used in piping in about pump and pipe rack area.</br> Eccentric reducer is most commonly used and often eccentric reducer used in piping in about pump and pipe rack area.</br> These reducers are used in various applications that involved in high pressure, vibration & temperature. These reducers are widely used in chemical, petroleum, shipbuilding, gas, power sectors.

MOREStainless Steel/Carbon Steel/Alloy Tee

Tee is also known as tee or tee pipe fittings, tee joints, etc. Mainly used to change the direction of the fluid, used in the main pipe to branch pipe. Can be classified by pipe size. Generally made of carbon steel, cast steel, alloy steel, stainless steel, copper, aluminum alloy, plastic, argon, pvc and other materials.

MOREStainless Steel/Carbon Steel/Alloy Elbow

An elbow is a pipe fitting installed between two lengths of pipe or tubing to allow a change of direction, usually a 180° or 90° angle, though 45° elbows are also made. The ends may be machined for butt welding (SW) or socketed welding(SW) etc.

MORE